Scaffold netting, also known as debris netting, is a safety measure used in construction and renovation projects. It is installed on scaffold structures to prevent debris, tools, and equipment from falling off and causing accidents or damage to the surrounding area.

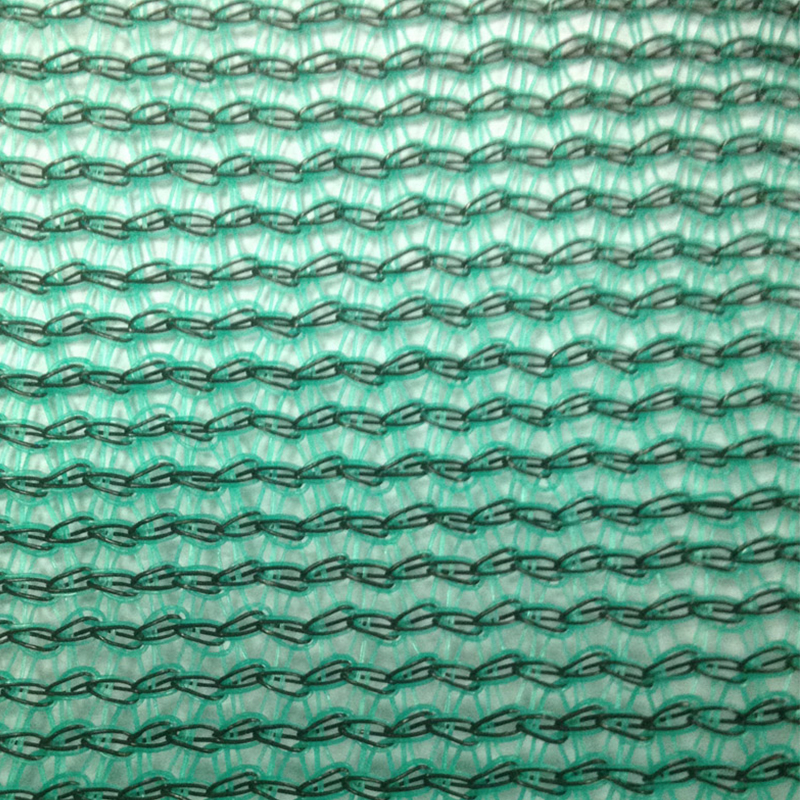

Scaffold netting usually consists of a woven or knitted material, typically made from high-density polyethylene (HDPE) or polypropylene (PP). These materials are lightweight, durable, and resistant to UV rays, making them suitable for outdoor use.

Here are a few key points to know about scaffold netting:

1. Safety: The primary purpose of scaffold netting is to enhance safety on construction sites. It acts as a barrier, preventing objects from falling off the scaffold and reducing the risk of injuries to workers and pedestrians below.

2. Debris Containment: Scaffold netting also helps contain debris, dust, and small objects that may be generated during construction or renovation work. It helps maintain a cleaner and safer work environment.

3. Wind Protection: In addition to debris containment, scaffold netting can provide some level of wind protection. It reduces wind resistance, preventing strong gusts from affecting the stability of the scaffold structure.

4. Privacy and Shade: Scaffold netting can also offer a degree of privacy and shade for workers. It creates a barrier that limits visibility from outside the construction site and provides some relief from direct sunlight.

When using scaffold netting, it is important to follow the manufacturer's guidelines for installation and maintenance. Regular inspection of the netting is necessary to ensure its integrity and effectiveness.

Please note that specific regulations and standards for scaffold netting may vary depending on the region or country. It is recommended to consult local authorities or industry experts for detailed information and compliance requirements in your area.

scaffold netting can be customized to meet specific requirements and applications. Customization options include:

1. Size and Dimensions: Scaffold netting can be customized to fit the specific dimensions of the scaffold structure. It can be tailored to cover the desired area effectively.

2. Color: Scaffold netting is available in various colors, typically in high-visibility options like orange or green. However, it can be customized to match specific branding requirements or aesthetic preferences.

3. Printing: Custom printing on scaffold netting is possible, allowing for logos, company names, or safety messages to be displayed. This can help enhance brand visibility and convey important safety information.

4. Durability and Strength: Scaffold netting can be customized to meet specific durability and strength requirements. For example, if a project involves heavier debris or equipment, a higher-strength netting material or reinforced edges can be used.

5. Flame Retardant: In certain situations, such as working near flammable materials, scaffold netting can be customized to be flame retardant. This helps minimize the risk of fire hazards.

When considering customization, it is important to work with a reputable supplier or manufacturer who specializes in scaffold netting. They can provide guidance on available customization options and ensure compliance with relevant safety standards and regulations.

It is advisable to consult local regulations and industry standards to ensure that any customization of scaffold netting aligns with the specific requirements in your area.

英语

英语 西班牙语

西班牙语